AMPACT

Aluminum Tap System

The proven AMPACT tap “C-spring” and wedge design provides a stored energy system that prevents connector degradation and achieves significantly lower resistance than any competitive product over the “in service” life of the connector. As thermal cycling causes the conductors to expand and contract, the AMPACT tap spring member flexes and maintains constant contact pressure.

- Installing taps takes a fraction of the time needed for conventional crimp-type connectors

- A locking tab prevents wedge from loosening once it has been driven into position. Every connection may be visually inspected by checking wedge movement and locking tab

- Taps may be used to connect multiple conductor combinations

- No damage to the conductors when installing or removing tap

- Lightweight, power-actuated tools require minimum operator effort

- “C” and wedge are factory coated with an inhibitor containing abrasive particles to help clean the contact surfaces during installation

- Individual tap packages are imprinted with applicable conductor combinations. Packages and labels are color coded to easily match taps with proper tool and cartridge combination

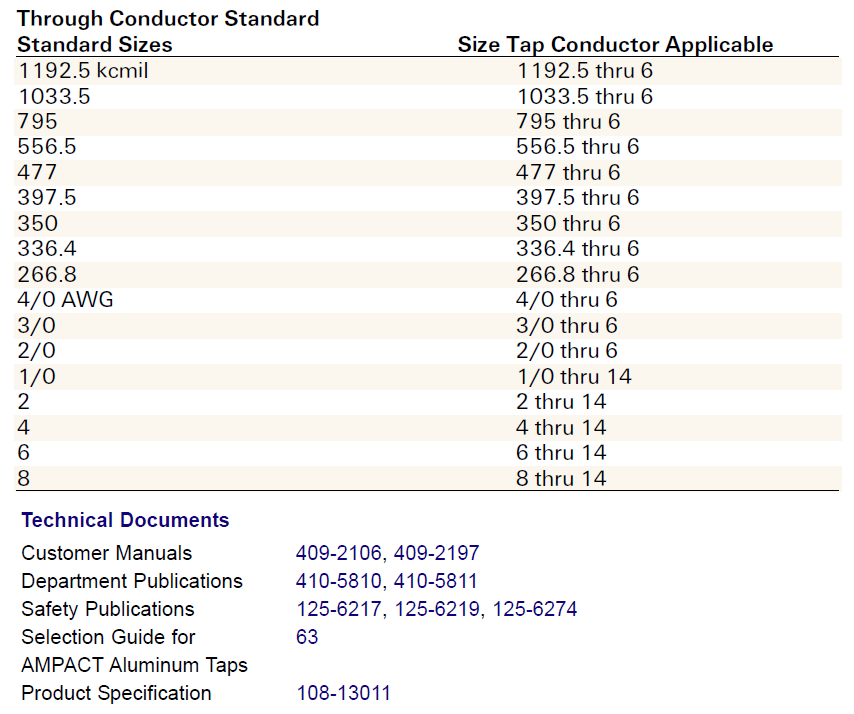

Aluminum Tap Conductor Combinations

The “C” and wedge are made of aluminum alloys. They are used to connect solid and stranded aluminum, aluminum alloy and stranded aluminum composite conductors including AAC, AAAC, ACSR, ACAR, AW, ACSR/AW, and ACSS. They may also be used in non-corrosive environments to connect copper conductors.

|

|

|

|---|---|---|

| Place tap on conductor | Attach AMPACT tool | Lock the tap |